High Hydrolysis resistance,Excellent clarity

Super UV resistance, non yellowing

Excellent Bonding Strength with Glass,Acrylic and PC

Used in Aviation, Transportation, Security and Building Curtain Glass

Excellent low temperature flexibility

Excellent Adhesion To Common Laminate Materials

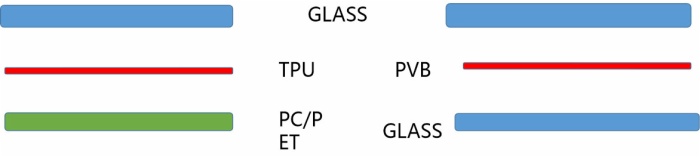

The combination of TPU and solid polycarbonate in ballistic protection glass lamination has revolutionized safety standards. It is also a leading example of how material innovation can transform personal safety and security. This technology offers a robust and versatile solution to protect people and infrastructure in diverse and challenging environments.

As research and development continue to advance, we are likely to see improvements in material efficiency, which could lead to lighter but equally strong glasses. In addition, optimized production processes could make this technology more accessible for various applications and industry sectors.

Mathiesen Group offers a range of TPU and Solid Polycarbonate products for companies dedicated to developing these security solutions.

| Vacuum |

|

Temperature

85℃

95℃ | |

Time

60 Min

30 Min | |

Vacuum degree

-100 kpa

-100 kpa |

The data is for reference only, the actual value will be different due to the thickness, specifications and design.

● This film has a minimum shelf life of 12 months. It should be stored in a cool and dry place with the original packaging of the manufacturer.

● Product thickness and width can be customized according to customer needs.